Scotstream Energy Technologies

Scotstream Generation Limited is an established Offshore Engineering company with over 35 years of experience in designing, building, installing and then operating complex offshore and subsea equipment.

Scotstream is in the process of developing a number of components that can be used for a range of renewable energy applications.

The Scotstream technology is protected by a number of Patents.

All of the Scotstream Technology is available under a licensing agreement.

This will enable all parties to have access to the technology. This business model will reduce costs and speed up the implementation of the technology.

Please contact Scotstream if you are interested in licensing any of the technology.

Features

Use of proven Offshore and Subsea technology

Lower CAPEX

Lower OPEX

Increased Generation and Availability

Lower Levelized Cost of Energy (LCOE)

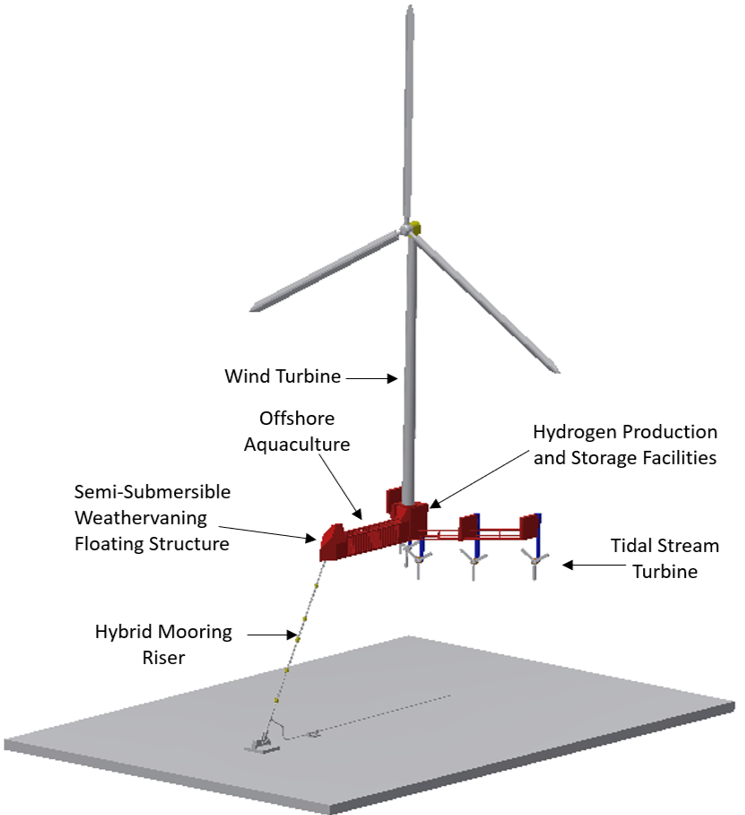

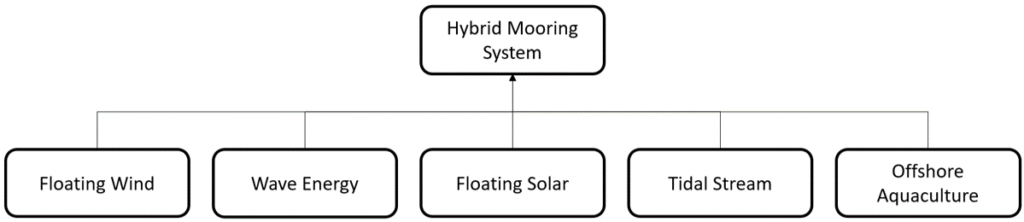

Hybrid Single Line Mooring System for weathervaning offshore floating applications

Scotstream is developing a hybrid single line mooring system that can be used on any weathervaning floating structure.

The key component in the riser assembly is the central riser pipe which acts as a dynamic J tube. The power umbilical is housed within the pipe and is protected during operation.

The riser assembly also comprises of a number of tension chains and buoyancy floats to manage the catenary of the mooring line during operation.

The foundation structure design will be dependent on the geotechnical seabed conditions and maybe a piled, gravity base or suction anchor design etc.

The interface on the floating structure comprises of a Continuity connecter. This avoid the requirement to used Slip Rings for high power transmission.

The Continuity Connector is a cable handling system that enabled full power to be transferred from the structure to the dynamic umbilical during continuous rotation of the structure.

The mooring system can be assembled and tested onshore and then towed to the offshore site. The mooring line can then be pulled down and connected into the foundation structure. The dynamic umbilical can then be pulled into the protection pipe and connected.

All of the existing floating renewables systems use multi leg mooring systems and an exposed dynamic umbilical. This is costly in terms of all the equipment capital cost and the vessel support required during installation and subsequent operations. The seabed area required and the environmental impact of multiple anchors is also an issue.

The single line hybrid mooring system will reduce Capex/Opex Costs and minimize the impact on the seabed environment.

The system can be used for a range of weathervaning floating energy applications. The applications can be combined one Multi-Purpose Platform (MPP) to reduce Capex/Opex and increase Revenue from the installation.

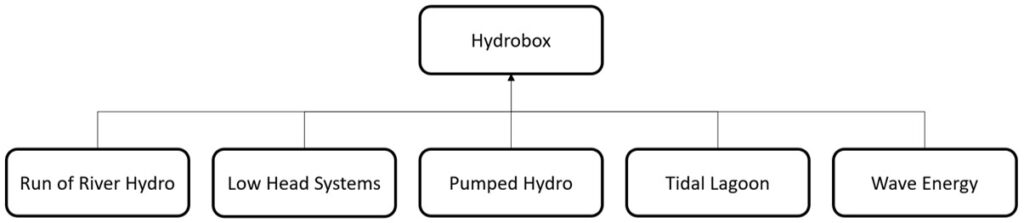

Hydrobox Generator for Low Head Hydro Applications

The Hydrobox is basically a waterwheel in a box. The design is based on an overshot waterwheel operating at over 80% efficiency.

The design incorporates a retaining shroud on the side of the wheel which enables much larger buckets to be used. This greatly increases the weight of water that can be retained on the wheel resulting in a very high rotational torque. Considerable power can be generated from a small package size.

The Hydrobox can operate on water head heights from 2 meters up to 10 meters. The length of the box can be specified to suit the water volume flowrate available.

The waterwheel can be packaged into a 6 meter or 12 meter long ISO shipping container to suit road transportation and sea freighting.

For larger diameter waterwheel applications, the components can be transported and then assembled on site.

The Hydrobox would be installed using inlet and outlet pipework to reduce the site civil works required.

The cost of the civil works is a major cost element of existing low head hydro systems. The combination of an easily installed Hydrobox coupled with standard pipework will considerably reduce the Capex Costs and the construction times required for low head hydro systems.

The Hydrobox technology can be used for a number of low head, high volume applications.