Continuity Connector

One of the main barriers to using weathervaning floating structures for offshore renewable energy applications has been the requirement to be able to continually transmit high MW electrical power from the rotating structure to the fixed dynamic umbilical.

The component normally used for rotary electrical transmission connections is a Slip Ring. This is a mechanical device that uses contacting brushes to transfer power from the rotating connection to the static connection. These components are available for small power capacities, however, have not been developed for multi MW operations. It may not be possible to develop a Slip Ring for this type of duty due to the power and heat involved. In general, Slip Rings are expensive, unreliable and are difficult to maintain in the field.

The lack of a suitably rated rotary connector may be the reason that the majority of the floating device developers have opted to use an expensive multi moored structure rather than a weathervaning structure.

The Spintral system uses a novel design of continuity connector to continuously transfer the power. This uses a continuous cable/connector system which does not have any rotary connection.

This avoids the requirement to use a slip ring and provides a continuous cable transmission system.

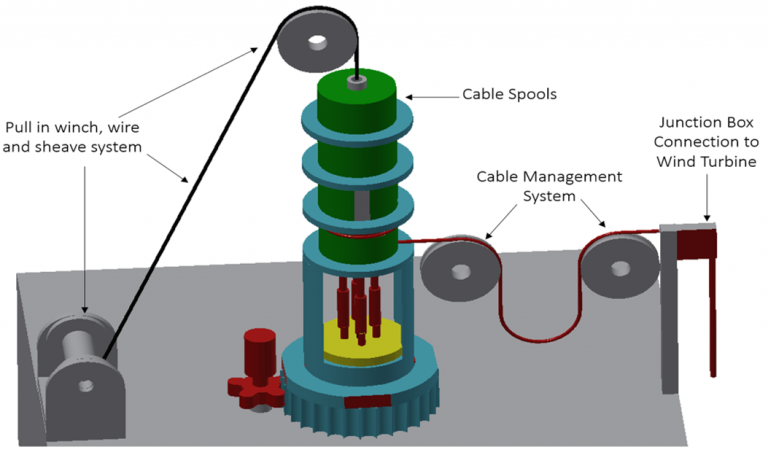

The mooring system and dynamic umbilical are integrated into a termination head that is locked off in the turret and supported by a slew bearing.

The dynamic umbilical is then connected directly into a series of cable spools mounted in the turret. The cables on each spool are then routed over catenary management sheaves to the connection point for wind turbine.

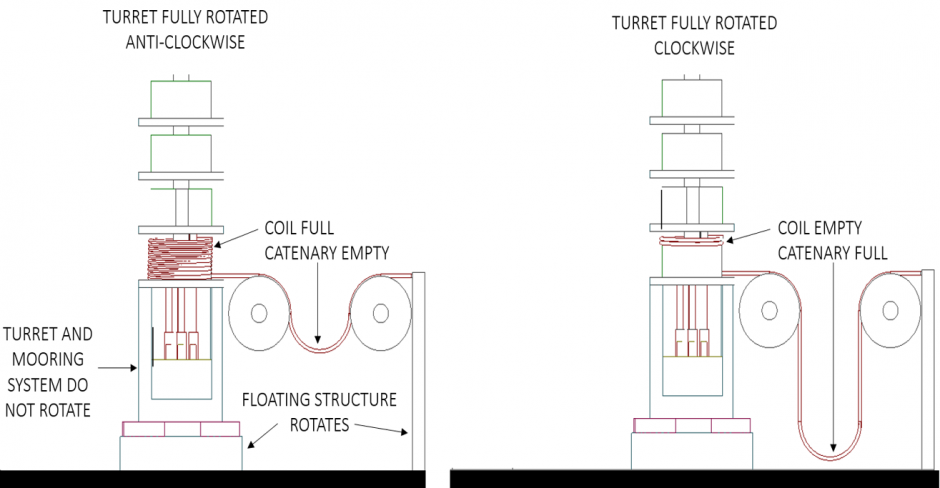

The mooring, termination head and turret do not rotate.

The floating structure and cable management system rotates about the mooring.

As the structure rotates clockwise about the turret, the cable is spooled from the coils onto the cable management system and forms a deeper catenary.

As the structure rotates anti-clockwise about the turret, the cable is spooled onto the coils from the cable management system and forms a shallower catenary.

The cable can rotate +/- 30 rotations before it has to be mechanically reset back to the starting position.

The Continuity Connector is an enabling technology that will, for the first time, allow a weathervaning floating structure to be used for a high power floating renewable energy application.